Originally from the city of Cixi in Zhejiang Province, Ms. Sun began her career in the Polyester staple fiber industry (PET) in 2001 as Deputy General Manager of Cixi Jiangnan Chemical Fiber Co, the parent company of JN Fibers/Sun Fiber. While there, she spearheaded the company’s import/export business. In 2013, Ms. Sun came to the U.S. and helped to establish the company’s two wholly-owned subsidiaries, JN Fibers, and Sun Fiber Recycling, Inc.

Established in 2013, JN Fibers focuses on the recycling and manufacturing of polyester staple fiber products. Located in South Carolina, the company has developed into a recycle and reuse manufacturing enterprise with a factory area of 600,000 square feet, a total annual production capacity of 60,000 tons, and annual sales of nearly 100 million U.S. dollars.

Facing unpreceded operational challenges in 2020, Ms. Sun, CEO & President of JN Fibers, has adopted a pragmatic and steady business style. While ensuring the supply of raw materials and safe production, the company has combined the sustainable development concept of “resource regeneration”, “energy and environmental protection” and “corporate social responsibility”, JN Fibers has gradually explored an environmentally friendly path to development, while also being deeply involved in the local community.

Interview

(originally conducted in Chinese, CLICK HERE for the Chinese version)

CGCC: How has the 2020 COVID pandemic affected your company’s business operations? Under your leadership, what measures did the company put in place to resolve these challenges?

SUN Ya: We experienced the most challenges from the middle of April 2020 to the beginning of May 2020 when we halted production for three weeks. After resuming work, we were unable to produce at full capacity due to the absence of some of the employees. Therefore, the actual product output in 2020 was 90% of normal production. To meet the demand of the market, we transferred products from our parent company, so in the end, the sales quantity was not affected. Because production was declining overall and expenses remained the same, the manufacturing cost per unit of product increased. Although under special conditions such as force majeure events, our contract with clients can be adjusted accordingly, we have not done so. Thus, we bear a lot of additional costs, which have a relatively large impact on our profits. In general, the annual output dropped by 10%, the sales volume was the same as in previous years, and the profit was affected by a year-on-year drop of about 50%, but overall it was still profitable.

We are a company with a large volume of logistics. During full production, the monthly throughput is 12,000 tons. Raw materials are mainly imported from overseas, and there will always be one month's worth of raw materials in transit. We still face continuous challenges in warehousing, capital, and raw material allocation

The factory operates 24 hours a day, seven days a week. The equipment cannot be stopped once it is turned on. If an employee is absent, the pressure on personnel and on-site management is very tough. However, all of these issues have been very well handled and all operations have been slowly back on track since the fourth quarter of 2020.

CGCC: The business of JN Fibers involves the recycling and reusing of materials to make fiber products. In recent years, transitioning to renewable energy has been a hot topic and an ongoing trend. As an experienced industry leader, in your view, what types of effects do you think this trend will have on the company’s current production as well as the future development of the industry?

SUN Ya: This trend definitely has great impacts, some positive and some negative.

On the positive side, our products use 100% recycled PET. In terms of product quality, it can replace native fiber. After entering the U.S. market, we have gradually been trying to promote the concept of regeneration in replacement of native fiber and it has been quite successful. Our products are beneficial to the company, to customers, and to society. It is a win-win for everyone and that’s why I’ve always believed that we have good prospects for development in the U.S.

The negative impact on our company is also evident. With the concept of environmental protection getting more and more attention and acceptance, more and more large companies are engaging in PET recycling, and it’s not only in the U.S., but also all around the world, especially in Europe. Compared with the direct production of packaging materials, recycling is more effective in reducing costs, directly affecting the company's raw material procurement costs, and affecting the competitiveness of the company's product price and profit.

In general, renewable energy is beneficial. From the perspective of technology and cost, low-carbon renewable energy is a promising industry. From our experience in this industry for more than 20 years, low carbon does not necessarily have to be costly. We can achieve a win-win in terms of economy and efficiency. Currently, our fiber factory focuses on the application of recycled materials, while the recycling plants in the United States trace back to the upstream recycling field, so it has greater social benefits.

CGCC: JN Fibers has always been focused on corporate social responsibilities, adding its own style/flair to the type of work it does. This is inseparable from your positive influence and management abilities at the company. What efforts have JN Fibers made in building relationships with the local communities in South Carolina? What advice you can offer in terms of developing a company’s relationship with the local community and government?

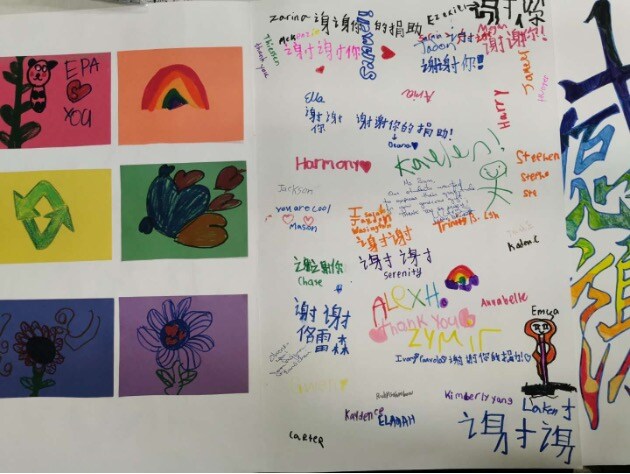

SUN Ya: I always believe that as a factory, the primary responsibility is to do one’s job well and to become a good factory. From the community's perspective, we are the highest-level members of the local economic development committee and take part in local events in support of the local economy. We also visit local high schools and provide recommendations and guidance to the students on ways to find jobs, and on how to treat and solve problems. Furthermore, we recently funded the construction of the library of a local bilingual school, and sponsored some of their athletic programs, etc.

We didn’t intentionally launch these community programs. As our company further developed, we naturally became active members of the community. I feel that the best way for us to foster a wonderful relationship with the local community and to build trust is through stable and healthy operations. Stable operations provide local employees with stable employment, salary, benefits, as well as a working environment and opportunities. It also contributes to local economic development. Because our production utilizes a large number of utilities (water, electricity, gas, natural gas, etc.), we have established a good relationship with various local utility suppliers through daily operations. Our customers are all over the United States, including many accessories suppliers and service providers. We have always made efforts to establish good business relationships with them.

So I think as the company becomes more well established, anything we can do to benefit the community and bring positive energy to the community, are ways in which we can further promote our company and the relationship it has built with the local communities. I think the most important thing is to be the best you can be and do everything within your capacity to benefit others. To be a good company is essential.

Visit https://sunfiberllc.com/ to learn more about JN Fibers